THE

FUTURE OF

CONVEYING.

TODAY.

THE

FUTURE OF CONVEYING. TODAY.

THE

FUTURE OF

CONVEYING.

TODAY.

THE

FUTURE OF

CONVEYING.

TODAY.

Smart choices today build stronger,

smoother material flow tomorrow.

Conveyor Design Essentials

Designing the right conveyor system is more than choosing equipment—it’s about engineering reliable material flow that fits your process. From screw conveyors and feeders to bucket elevators, belt conveyors, and flexible sidewall systems, this guide highlights the critical design factors that keep operations efficient, safe, and cost‑effective. Whether you’re moving fine powders, heavy lumps, or abrasive materials, you’ll find practical insights to help you select the right solution and extend the life of your equipment.

Smart choices today build stronger,

smoother material flow tomorrow.

Conveyor Design Essentials

Designing the right conveyor system is more than choosing equipment—it’s about engineering reliable material flow that fits your process. From screw conveyors and feeders to bucket elevators, belt conveyors, and flexible sidewall systems, this guide highlights the critical design factors that keep operations efficient, safe, and cost‑effective. Whether you’re moving fine powders, heavy lumps, or abrasive materials, you’ll find practical insights to help you select the right solution and extend the life of your equipment.

Conveyor Selection & Design Guide

A comprehensive engineering guide to selecting and designing screw conveyors, feeders, bucket elevators, belt conveyors, and flexible sidewall systems. This page helps process engineers, plant managers, and maintenance teams make informed decisions that improve flow, reduce wear, and extend equipment life.

A comprehensive engineering guide to selecting and designing screw conveyors, feeders, bucket elevators, belt conveyors, and flexible sidewall systems. This page helps process engineers, plant managers, and maintenance teams make informed decisions that improve flow, reduce wear, and extend equipment life.

Screw Conveyor & Feeder Selection and Design

Screw conveyors and feeders are the backbone of controlled material movement. Selecting the right configuration ensures predictable flow, reduced wear, and long-term reliability.

Key Variables That Shape Screw Conveyor Performance

Designing a screw conveyor is never one‑size‑fits‑all. Every application demands attention to:

- Material characteristics — size, weight, abrasiveness, temperature

- Rate & speed requirements

- Incline angle

- Trough style & mating equipment

- Flighting geometry

- Drive package torque & speed control

These variables determine how efficiently material moves—and how long your equipment lasts.

Drive Package: Controlling Speed & Torque

The motor and reducer drive package is the heart of the system. Proper sizing ensures the conveyor can start under load, maintain consistent speed, and deliver the torque required for dense or sticky materials.

Trough Selection: Matching Material & Process Equipment

The trough (housing) determines how material enters, moves, and exits the conveyor.

- U‑troughs are standard for most applications.

- Rectangular troughs extend life when handling abrasive materials.

- Oversized troughs (e.g., 12" screw in a 14" trough) allow material to ride on itself, reducing wear.

- Drop‑bottom troughs simplify cleanout when sanitation or product changeover is required.

Flighting Design: The Most Critical Component

Flight geometry determines how material is metered and conveyed. CSC recommends:

- Short pitch at the inlet to prevent compaction

- Full pitch after the inlet for smooth, non‑compacted flow

- Varied pitch for slotted inlets (48"+) to draw material evenly from hoppers

- Tapered screws as an alternative—though they may retain material in the trough

Special Design Considerations

High Temperature Materials

For materials above 300°, CSC incorporates a heat isolation chamber to protect the reducer and simplify installation.

Steep Inclines

For inclines above 25°, tubular trough screw conveyors maintain flow and prevent fallback.

Abrasive Materials

- Hard‑surfaced screws

- Oversized or rectangular troughs

- Air‑purge seals to prevent leakage

- Explosion protection per NFPA 68 when required

Bucket Elevator Selection & Design

Bucket elevators provide vertical conveying for a wide range of materials. Choosing the right style ensures efficiency, reduced degradation, and long equipment life.

Centrifugal vs. Continuous Elevators

Centrifugal Elevators

Best for: fine, free‑flowing materials

- Operate at 250–300 fpm

- Use centrifugal force to discharge material

- Ideal for high‑throughput applications

Continuous Elevators

Best for: fragile, heavy, or large‑lump materials

- Operate at ~125 fpm

- Gentle handling minimizes degradation

- Excellent for materials that must remain intact

Bucket Elevator Construction Options

Belt Type Elevators

- Ideal for abrasive, dry, free‑flowing materials

- Limited in high‑temperature applications

Chain Type Elevators

- Handle heavier loads and greater heights

- Suitable for high‑temperature materials

- Use sprockets for positive alignment

Standard Casing Sizes

- 10”×36”

- 16”×40”

- 16”×48”

- 24”×48”

- 24”×54”

Safety & Compliance

Explosion protection available per NFPA 68 for sensitive materials.

NOTES

The application of Flexible sidewall conveyor is dependent on many factors as outlined above.

Because of their special design these type of belt are expensive to manufacture along with the associated pulley and deflection wheels.

Screw Conveyor & Feeder Selection and Design

Screw conveyors and feeders are the backbone of controlled material movement. Selecting the right configuration ensures predictable flow, reduced wear, and long-term reliability.

Key Variables That Shape Screw Conveyor Performance

Designing a screw conveyor is never one‑size‑fits‑all. Every application demands attention to:

- Material characteristics — size, weight, abrasiveness, temperature

- Rate & speed requirements

- Incline angle

- Trough style & mating equipment

- Flighting geometry

- Drive package torque & speed control

These variables determine how efficiently material moves—and how long your equipment lasts.

Drive Package: Controlling Speed & Torque

The motor and reducer drive package is the heart of the system. Proper sizing ensures the conveyor can start under load, maintain consistent speed, and deliver the torque required for dense or sticky materials.

Trough Selection: Matching Material & Process Equipment

The trough (housing) determines how material enters, moves, and exits the conveyor.

- U‑troughs are standard for most applications.

- Rectangular troughs extend life when handling abrasive materials.

- Oversized troughs (e.g., 12" screw in a 14" trough) allow material to ride on itself, reducing wear.

- Drop‑bottom troughs simplify cleanout when sanitation or product changeover is required.

Flighting Design: The Most Critical Component

Flight geometry determines how material is metered and conveyed. CSC recommends:

- Short pitch at the inlet to prevent compaction

- Full pitch after the inlet for smooth, non‑compacted flow

- Varied pitch for slotted inlets (48"+) to draw material evenly from hoppers

- Tapered screws as an alternative—though they may retain material in the trough

Special Design Considerations

High Temperature Materials

For materials above 300°, CSC incorporates a heat isolation chamber to protect the reducer and simplify installation.

Steep Inclines

For inclines above 25°, tubular trough screw conveyors maintain flow and prevent fallback.

Abrasive Materials

- Hard‑surfaced screws

- Oversized or rectangular troughs

- Air‑purge seals to prevent leakage

- Explosion protection per NFPA 68 when required

Bucket Elevator Selection & Design

Bucket elevators provide vertical conveying for a wide range of materials. Choosing the right style ensures efficiency, reduced degradation, and long equipment life.

Centrifugal vs. Continuous Elevators

Centrifugal Elevators

Best for: fine, free‑flowing materials

- Operate at 250–300 fpm

- Use centrifugal force to discharge material

- Ideal for high‑throughput applications

Continuous Elevators

Best for: fragile, heavy, or large‑lump materials

- Operate at ~125 fpm

- Gentle handling minimizes degradation

- Excellent for materials that must remain intact

Bucket Elevator Construction Options

Belt Type Elevators

- Ideal for abrasive, dry, free‑flowing materials

- Limited in high‑temperature applications

Chain Type Elevators

- Handle heavier loads and greater heights

- Suitable for high‑temperature materials

- Use sprockets for positive alignment

Standard Casing Sizes

- 10”×36”

- 16”×40”

- 16”×48”

- 24”×48”

- 24”×54”

Safety & Compliance

Explosion protection available per NFPA 68 for sensitive materials.

NOTES

The application of Flexible sidewall conveyor is dependent on many factors as outlined above.

Because of their special design these type of belt are expensive to manufacture along with the associated pulley and deflection wheels.

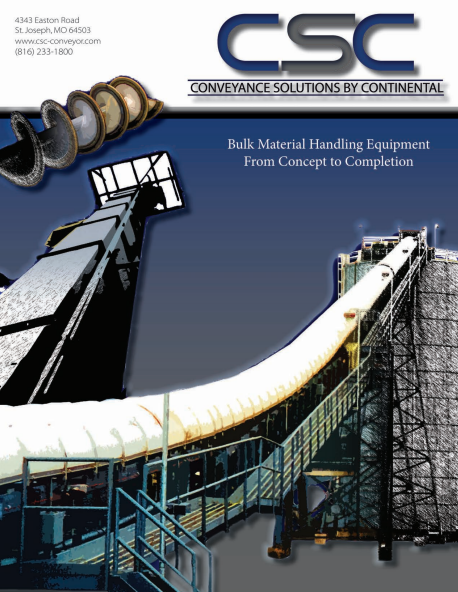

Precision Conveyance, Engineered for Every Flow

Discover how

Conveyance Solutions by Continental (CSC) transforms bulk material handling from concept to completion. With nearly a century of expertise, CSC designs and manufactures screw conveyors, feeders, bucket elevators, and belt conveyors built to meet the toughest industrial demands. This brochure highlights our engineering capabilities, customization options, and proven solutions that keep operations efficient, safe, and reliable worldwide.

Contact us today or fill out the Inquiry Data Sheet to receive your quote.

INQUIRY DATA SHEET

Contact us today or fill out the Inquiry Data Sheet to receive your quote.

INQUIRY DATA SHEET

Contact US TODAY

Fill out the form, and we'll be in touch with you soon.

Contact Us Today

Thank you for contacting us.

We will get back to you as soon as possible.

Oops, there was an error sending your message.

Please try again later.